Neal Feay/MV Anderson

In my 2018 JustLuxe interview with Alex Rasmussen, founder of Neal Feay Studio, we discussed the emergence of his design/manufacturing company as the leader in the creation of high-end furniture, textured art design, fashion, and exterior cladding using anodized aluminum as the major element in their creative product lines.

For decades, Neal Feay Studio specialized in anodized aluminum designs. The company initially found success decades ago in jewelry design, then transitioned to design and manufacturing Hi-Fi Audio systems all from aluminum. As the company grew, Neal Feay with Alex Rasmussen at the helm steadily expanded into high fashion, architectural, and yacht categories. The company counts Louis Vuitton, Marc Newson and Azzedine Alaïa, as their collaborators.

But now, something new.

Alex Rasmussen and the Neal Feay Studio team are partnering with Vyaire Medical, to create anodized aluminum ventilators to fight COVID-19. Neal Feay Studio now produces hundreds of Vyaire Medical ventilator systems to meet exponential demand. How did this practical art/design studio have the knowledge and intuition to work with Vyaire Medical, one of the world’s most respected medical equipment providers? It relates to their experience and deep knowledge of anodized aluminum.

Recently, we were fortunate to be able to interview Mr. Rassmussen and ask.

JustLuxe: What advantages does anodized aluminum have in the production of ventilators to combat COVID 19?

Rasmussen: Our special anodized aluminum is perfect for the production of medical equipment. It’s incredibly strong and light, reducing the overall weight of the ventilator, making it easier to transport. Aluminum is also much easier to disinfect. Unlike plastic, our designs can withstand cleaning from strong solvents with no degradation issues at all. It’s incredibly durable, and all also highly recycled content.

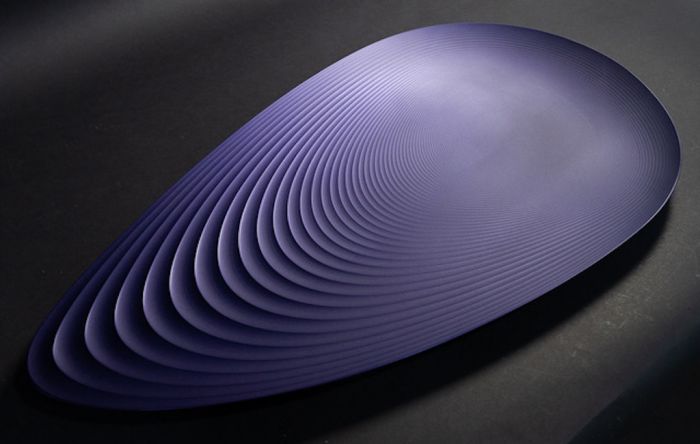

Moon Console, furniture from Neal Feay studio

JustLuxe: Neal Feay is known for high-end fashion and architectural projects, tell us about how the partnership with Vyaire Medical happened?

Rasmussen: We have been working with the company that owns Vyaire for over 15 years. This type of work was actually our bread and butter until 2008. Our work in fashion, design and architecture has all been since then.

JustLuxe: With speed being such a factor in the face of the pandemic, how did you ramp up manufacturing so quickly?

Rasmussen: Because we are vertically integrated, and work day and night, it puts us in an unusual position of being able to react extremely quickly. By shifting priorities, we changed machines making luxury accessories to making Vyaire panels in a matter of days. The fact that France had been locked down had opened up quite a large amount of our capacity. The bad news and the good news were very much related…. We began shipping in five calendar days, rather than a typical 8 weeks of lead time.

JustLuxe: Neal Feay seems to buck the trend when it comes to moving manufacturing out of the country. How have you managed to continue making things right in Santa Barbara?

Rasmussen: My grandfather started the company in 1945 to make world class products. We have been refining our métier for three generations. We have another large medical customer, and they were previously using Chinese suppliers. By doing smart industrial design that leverages our knowledge of what is possible with our material, we provided a superior cost to perceived value product.

JustLuxe: Right now, have you transitioned completely over to ventilator production, or is Neal Feay still working in its traditional categories of fashion and architecture?

Rasmussen: Oh, no… we have been up to all sorts of creative things — a BBJ interior, several superyachts, a new line of luxe outdoor furniture that will be Alex Rasmussen for Sutherland furniture. We are always moving in new directions.

Neal Feay studio

Art installaion, anodized aluminum wave, Neal Feay Studio

Neal Feay Studio

Exterior Cladding, Neal Feay Studio

Neal Feay Studio

Exterior Design, Vyaire Ventilator, Neal Feay Studio